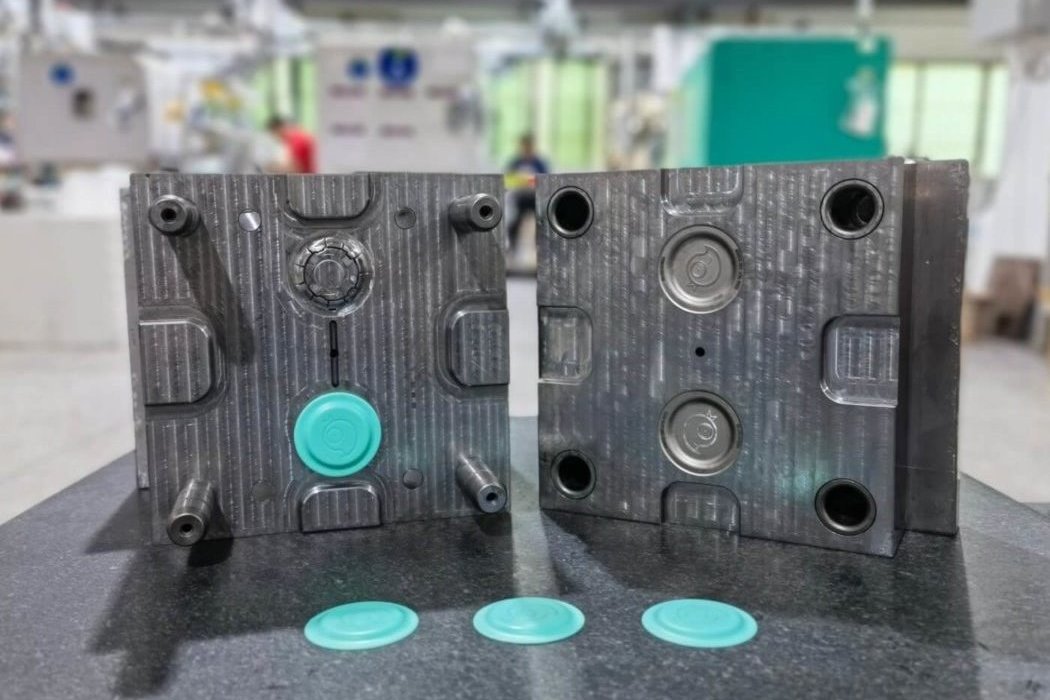

Rapid tooling, sometimes known as prototype tooling or bridge tooling, is a fast and cost-efficient way to carry out low-volume injection molding for a variety of types of plastic parts. Once the aluminum or steel mold has been created with the rapid tooling process, it can be utilized as part of a molding process to create multiple copies of a part. Rapid tooling is therefore used to create moldings for rapid prototyping needs in a shortened timeframe, or to bridge the gap before high-volume production.

The rapid tooling process involves the creation of a mold using aluminum or soft steel, a stocked mold base, and hand-load inserts. Rapid tooling is one of the best methods for fulfilling small batch orders meant for use in marketing samples, product evaluations, and process design.

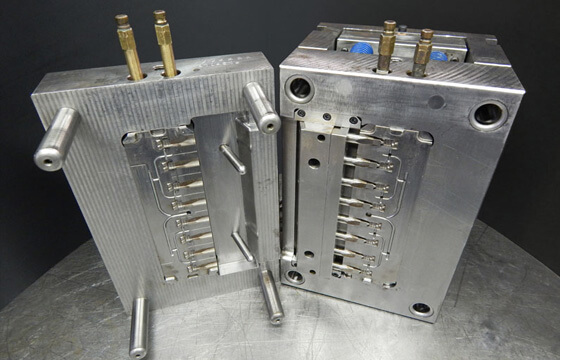

Traditional tooling is often prohibitively expensive for small projects. Our custom rapid tooling service is a cost-effective, low-volume alternative in situations where large volumes of the part won’t be needed in the future. The rapid production tooling process is commonly used in industrial settings for prototyping solutions or for diagnosing design issues, providing an easy introduction to mold making.

At 3ERP, we typically create rapid molds by CNC machining and EDM, though we also sometimes use additive methods such as 3D printing technologies.