Along with injection molding, plastic extrusion is one of the most widely used manufacturing processes for the forming of plastics, and the most widely used for thermoplastics. It is used to create objects with a continuous profile such as pipes, tubing, and door profiles.

Thermoplastic extrusion in its current form has existed for almost a century, but it remains a powerful tool for high-volume production of continuous profile parts. Customers work with plastic extrusion companies to create a custom plastic extrusion for a part, usually in high volumes but sometimes — as with 3ERP — for low-volume production.

This article covers the basics of plastic extrusion, including how the process works, what kinds of thermoplastic can be extruded, what products plastic extrusion is used to make, and a comparison of plastic extrusion with aluminum extrusion.

The plastic extrusion process

To understand the plastic extrusion process, it is useful to get a picture of what an extruder is and how it works. Typically, an extruder contains the following parts:

- A hopper, where the raw plastic is kept

- A feedthroat, where the plastic enters the barrel from the hopper

- A heated barrel, containing a screw driven by a screw drive motor that forces material to the feedpipe

- A breaker plate, fitted with screens to filter the material and maintain pressure

- A feedpipe, where the now molten material exits the barrel and is delivered to the die

- A die, which shapes the material into the desired extrusion profile

- A separate cooling system, which helps the extrusion solidify evenly

The plastic extrusion process starts with filling the hopper with solid raw material in the form of, for example, pellets or flakes. The material is gravity fed through the feedthroat and into the extruder barrel.

Once the material enters the barrel, it begins to be heated via three or more heat zones. (The heat zones may be cooler near the feedthroat and hotter near the die, to allow for gradual melting.) As it is being heated, the material is simultaneously pushed towards the die end of the barrel by a reciprocating screw, which is driven by a motor. The screw and pressure also generate heat, so the heat zones themselves do not have to be as hot as the required extrusion temperature.

The molten plastic exits the barrel through a screen reinforced by the breaker plate. This screen removes contaminants from the material and maintains even pressure within the barrel. The material passes through a feedpipe into the custom-built die, which has been machined with an opening shaped like the desired extrusion profile to create a custom plastic extrusion.

When forced through the die, the material assumes the shape of the die opening, finishing the extrusion process. Once fully through the die, the extrusion profile is cooled in a water bath or via a set of cooling rolls, causing it to solidify.

Extrusion plastics

Plastic extrusion works with a number of different thermoplastics. These materials are heated to a temperature high enough to melt the material but not so high as to cause thermal decomposition. This temperature differs from one extrusion plastic to the next.

Extrusion plastics are typically fed into the extruder in the form of plastic pellets, similar to those used for injection molding. Other forms include powders, flakes, and granules.

Common extrusion plastics include:

- Polythene (polyethylene): Extruded between 400°C (low density) and 600°C (high density)

- Polystyrene: ~450°C

- Nylon: Between 450°C and 520°C

- Polypropylene: ~450°C

- PVC: Between 350°C and 380°C

In certain cases, the desired extrusion plastic may be an elastomer or a thermoset instead of a thermoplastic.

Plastic extrusion applications

Plastic extrusion companies can make a variety of parts, just as long as the part has a consistent profile. Plastic extrusion profiles are ideal for tubing, door profiles, automobile parts, and more.

Pipes and tubing

Plastic piping and tubing, sometimes made from PVC or the aforementioned thermoplastics, is a common plastic extrusion application because it has a simple cylindrical profile. Exterior gutters are one example of extruded tubing.

Wire insulation

Many thermoplastics have excellent electrical insulation and thermal stability, making them suitable for extruded wire and cable insulation and jacketing. Plastic extrusion companies may also use fluoropolymers for this purpose.

Window and door profiles

Plastic door and window frames are highly suited to extrusion due to their continuous profile and length. PVC is a popular material for this plastic extrusion application and all plastic extrusion profiles related to household fittings.

Blinds

Window blinds (shades) consisting of many identical slats may be extruded using a thermoplastic. The profile is typically a short length, sometimes with one side rounded. Polystyrene is commonly used for faux wooden venetian blinds.

Weatherstripping

Plastic extrusion companies often make weatherstripping products — draft excluders, for example, whose plastic extrusion profiles are designed to fit closely to door and window frames. Rubbers are common weatherstripping materials.

Windshield wipers and squeegees

The windshield wiper of an automobile is usually extruded. The extrusion plastic may be a synthetic rubber material like ethylene propylene diene methylene, or the plastic extrusion company may perform co-extrusion of a synthetic rubber with a natural rubber. Manual squeegee blades work in a similar way to windshield wipers.

Plastic extrusion vs aluminum extrusion

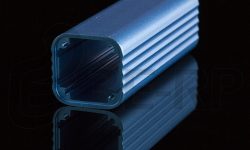

In addition to thermoplastics, it is possible to extrude aluminum parts with a continuous profile.

Advantages of using aluminum for extruded parts include lightness, conductivity, and recyclability, and common aluminum extrusion applications include bars, tubes, wire, piping, fencing, tracks, frames, and heat sinks.

Unlike plastic extrusion, aluminum extrusion can be either hot or cold: hot extrusion takes place at a temperature between 350°C and 500°C, and cold extrusion takes place at room temperature. Learn more about aluminum extrusion.

3ERP is one of a select group of companies offering low-volume custom plastic extrusion. Most plastic extrusion companies will not accept small orders, but 3ERP and our network of partners can accommodate your prototyping and short-run production needs. Get in touch for a free quote.