Injection molding allows manufacturers to create plastic parts from a wide range of thermoplastic polymers. But what about when the product is better suited to a thermosetting polymer like a polyurea or polyester?

Thermoplastic pellets can be melted down and injected into a mold cavity, where they harden, but thermosets do not behave in this way. For a thermoset to harden, it must be cured via heat, radiation, or mixing with a catalyst. The standard injection molding process does not permit this.

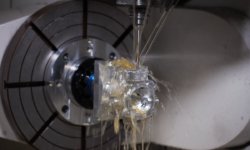

Fortunately, it is possible to mold thermosets using the process of reaction injection molding (RIM), which was developed in the 1960s for the production of more impact-resistant automotive parts. Instead of melting down solid pellets, this form of injection molding using a special mixer to combine the two liquid parts of the thermosetting polymer and cause a chemical reaction that allows the material to cure and harden once injected into the mold cavity.

This article goes over the basics of reaction injection molding, looking at the available materials and the main advantages and disadvantages.

How does reaction injection molding work?

Reaction injection molding works by mixing two parts of thermosetting polymer that react and cure when combined. The mixture is injected into a mold cavity, where the curing takes place, allowing the material to solidify and form a part shaped like the mold cavity.

Although reaction injection molding tooling can closely resemble the molds used for standard injection molding, a special type of injection molding machine is needed for the RIM process. This machine usually comprises the following components:

- Two tanks for storing the two liquid parts of the thermoset

- High-pressure pumps for moving and metering the liquids

- Mixhead for blending and dispensing the two liquids

- Mold for forming the thermoset into the desired shape

High pressures are required to move the liquids from the tanks to the impinging mixer, where they are mixed at a high velocity (1200 psi). However, the mixed material can often be injected into the mold at relatively low pressure. This is because the thermosets are typically less viscous than the molten thermoplastics used in standard injection molding. For similar reasons, the mold often does not have to be made from extremely hard tool steel, allowing low-cost aluminum molds to be used, and the cavity can have sections of varying thickness since there is minimal risk of the parts warping while they cure. The mold is typically heated to a moderate temperature to facilitate the curing process, unlike in other forms of injection molding where coolant helps to speed up solidification.

Curing of the thermoset within the mold usually takes between one and seven minutes, depending on the material used and the geometry of the mold cavity.

Reaction injection molding is similar to liquid silicone injection molding, although the latter does not require high-pressure mixing of the two components of the silicone.

Process variants

Added steps can be added to the RIM process to alter the type of parts produced. Reinforced reaction injection molding (RRIM) involves the use of additives such as glass fibers, which are fed to the impinging mixer via a separate channel. This results in parts with improved strength.

Another way to improve the strength of the molded parts is to use a fiber mesh — pre-arranged within the mold cavity — as a reinforcing agent. This variant is called structural reaction injection molding (SRIM).

Reaction injection molding materials

Several thermosets can be used in reaction injection molding. The most common materials are:

- Polyurethanes

- Elastomeric polyurethanes

- Polyurethane foams

- Structural

- Rigid

- Flexible

- Polyureas

- Polyisocyanurates

- Polyesters

- Polyphenols

- Polyepoxides

- Nylon 6

Reaction injection molding benefits

There are many advantages of reaction injection molding. Besides simply offering a way to produce molded parts with thermosetting polymers, the process also has a few benefits over standard injection molding.

Due to the low-viscosity liquid materials, it is possible to create large, thin-walled parts. And because the parts do not thermally contract within the mold, it is also possible to have varied wall thickness throughout the part if needed. Low clamping forces are required due to the low injection pressure, reducing setup time and cost. Additionally, low-cost aluminum molds are sufficient for many parts.

Because of the materials used, reaction injection molded parts are typically lightweight and flexible, which can be beneficial in many applications. RIM foams have a low-density core with a tough, high-density skin.

Limitations

One disadvantage of RIM is the high cost of raw materials compared to thermoplastics. Another is the requirement for a dedicated RIM machine. Additionally, cycle times are slower than standard injection molding, though they are faster than other thermoset forming processes like vacuum casting.

Reaction injection molding applications

Reaction injection molding is a valuable process for creating lightweight parts such as automotive components and high-strength packaging foams.

In the automotive industry, where the very first applications of reaction injection molding were devised in the 1960s, RIM is today widely used to make parts like bumpers, air spoilers, fenders, body panels, trunk covers, and insulated cab flooring. Other uses can be found in areas like sporting equipment (internal helmet foams, for example), furniture, packaging, enclosures for electronic devices, and machinery housings. RIM may also be preferred over injection molding for unique geometries (such as oversize parts with varied wall thickness) or for overmolding and insert molding.

Molding with 3ERP

3ERP offers several injection molding services, including thermoplastic, silicone, and metal injection molding. We also offer a reliable and affordable urethane casting service for rigid or flexible parts. Contact us for a free quote.