Online manufacturing platforms are the most popular places to order rapid prototypes and production parts, you just have to upload your 3D CAD files, fill in the information about material, quantity, and surface finish, and you will have the quotation in seconds. If you are happy with the price, you can order straight away.

Online quotation systems certainly speed up the ordering process. But does that means traditional manufacturing companies are now out of the picture? Personally, I don’t think so, and in the article I’ll try to explain why.

Most online platforms now use AI to provide instant online quotations. And a process like 3D printing, whether plastic or metal, the price given by the AI system is almost always accurate. It is very easy to calculate costs for types of additive manufacturing processes. From the weight and volume of the parts, the system can immediately give you a precise manufacturing time and cost. The only thing the AI might miss is the possibility of deformation. AI system can also give accurate injection molding and die casting quotations, because, as with 3D printing, the cost is based on the weight. There are also well-developed software tools for analyzing mold design.

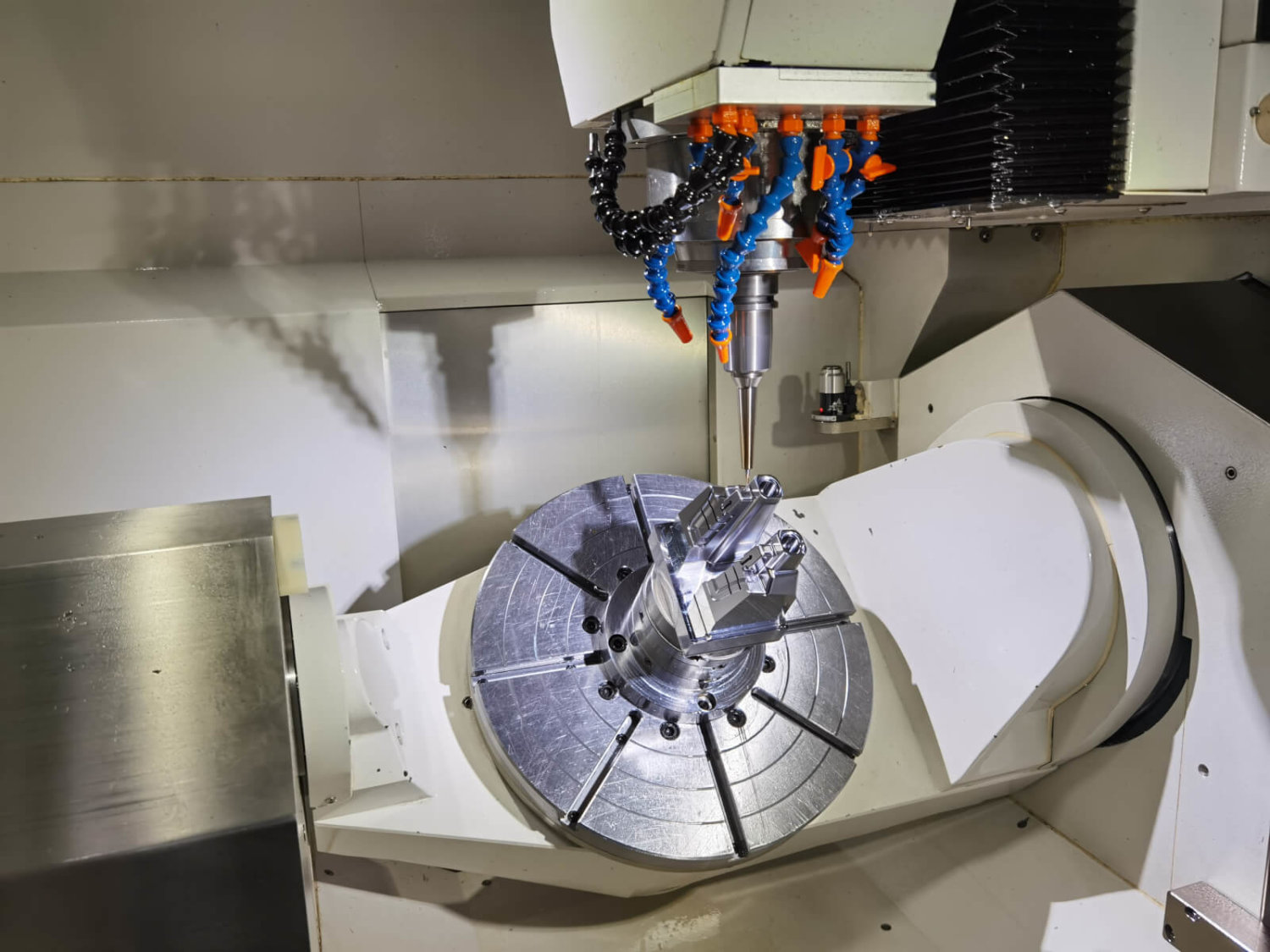

But what about online CNC machining quotations, and quotations for other manufacturing processes? Out of curiously, I ran a test to see whether an online platform with an AI quotation system could provide accurate CNC machining quotes.

First of all, I made CAD file of a cube measuring 100 x 100 x 100 mm. I then uploaded it and chose aluminum 6061 with no finish. This was the price I got, which seems slightly high, the cube has no other features and the machining time will therefore be short.

Expedite $239.80 Made Locally | Standard $166.97 Made Locally| Economy $95.26 Made internationally

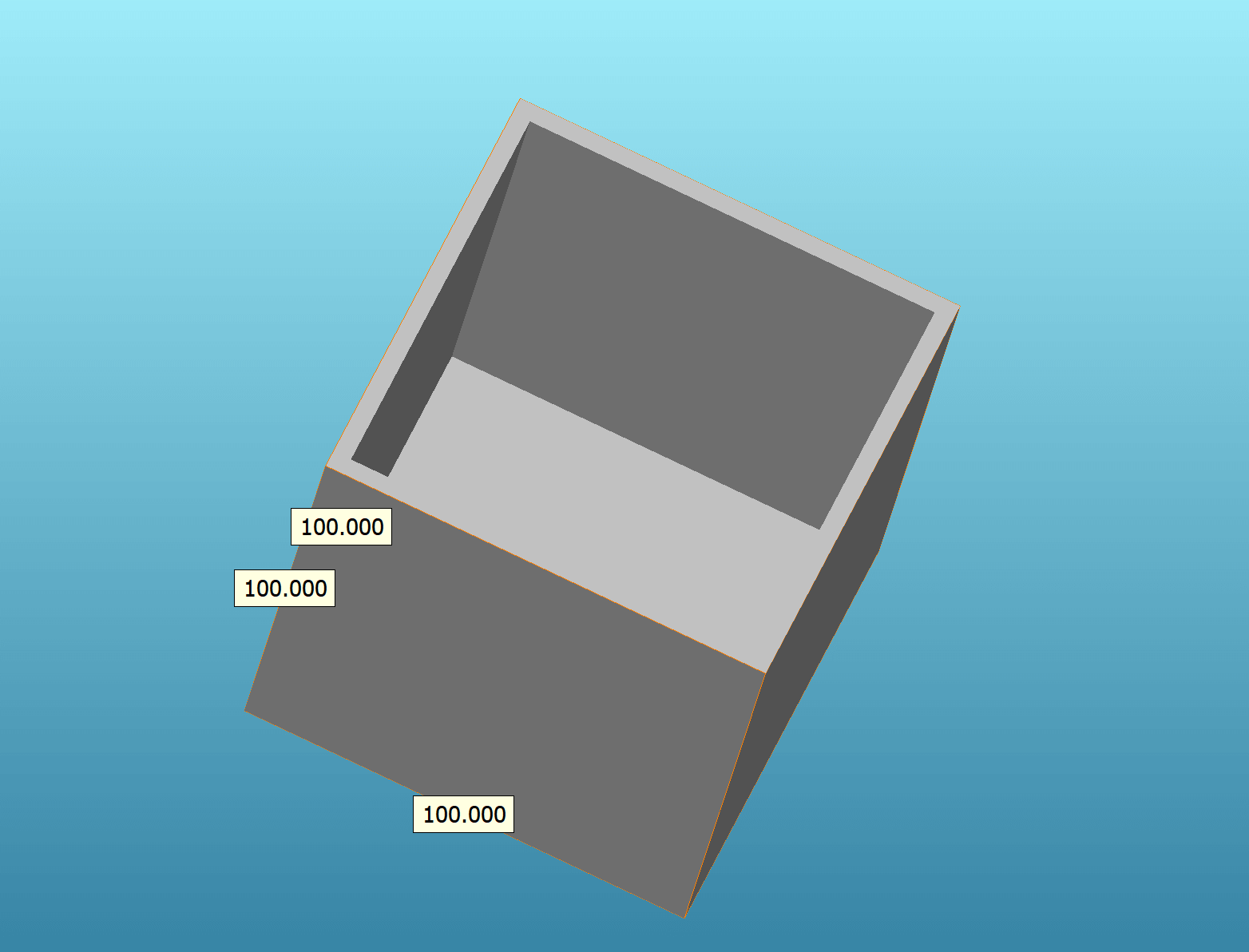

Next, I modified the CAD file, removing the material from the inside. Here is a picture of the design.

And here is the price I got. Overall, fair enough.

Expedite $609.45 Made Locally | Standard $364.17 Made Locally | Economy $160.44 Made internationally

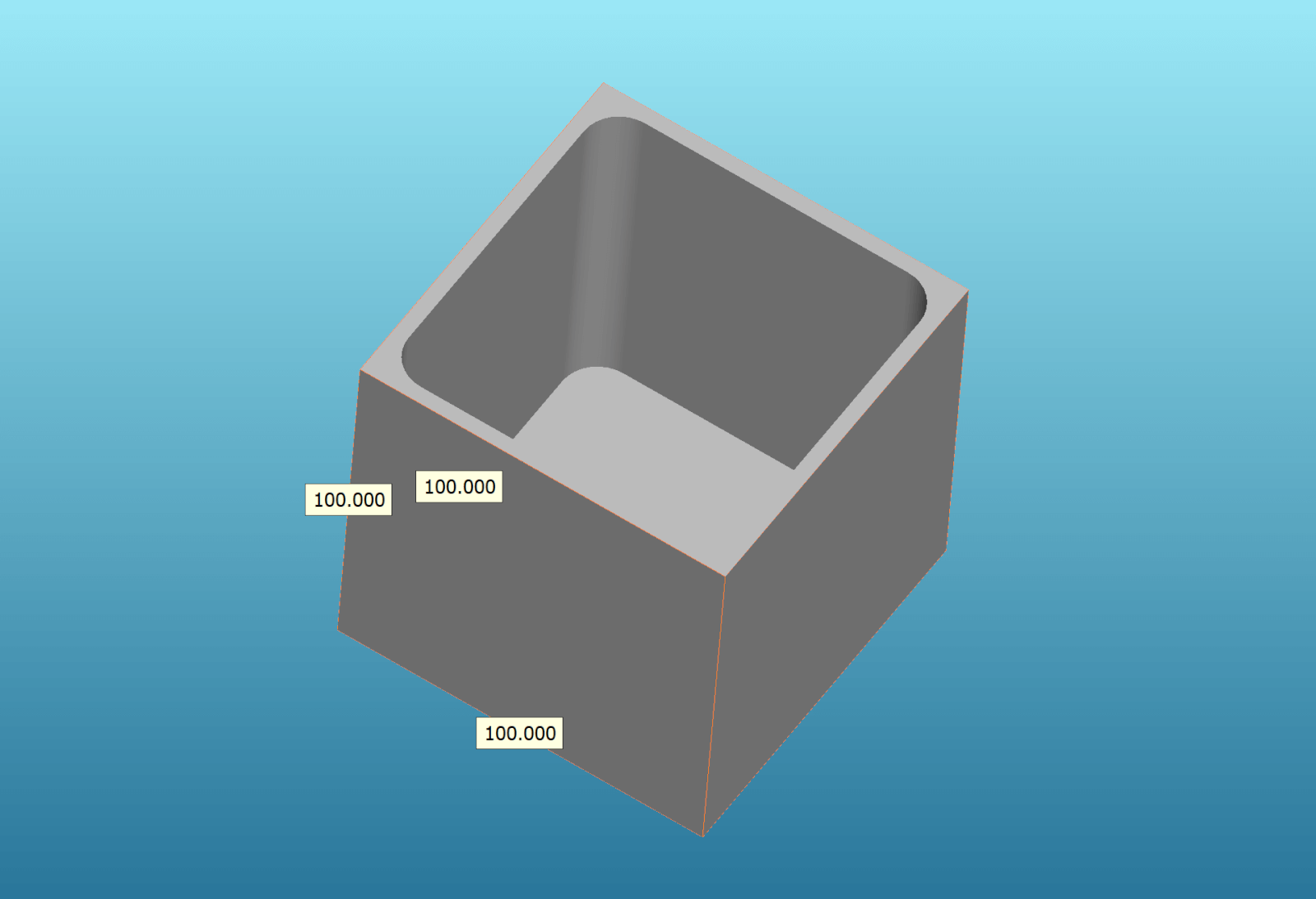

Experienced engineer will know that the sharp corners are a problem for CNC machining, and would have to be finished by EDM. So to make it easier, I then added radii to the sharp corners.

Expedite $771.91 Made Locally | Standard $475.46 Made Locally | Economy $208.55 Made internationally

Obviously, the AI considers the radii as extra features when I actually added them to simplify the manufacturing process. The online quotation system is penalizing thoughtful design!

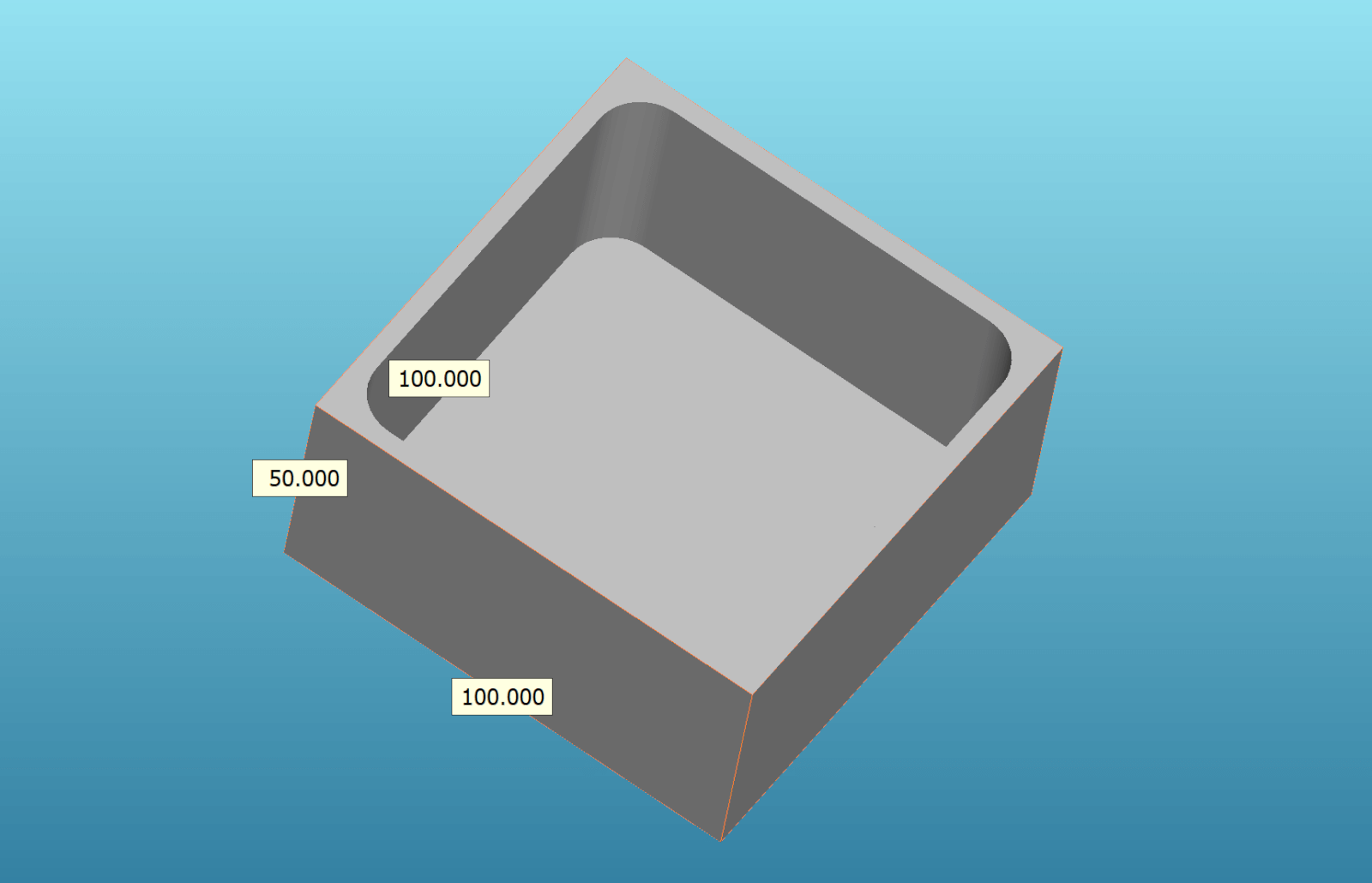

In order to test the AI further, I made another adjustment to my CAD file, making the height 50 mm instead of 100 mm. This would allow the manufacturer to use much shorter cutting tools, and also significantly shorten the machining time: our own testing has shown that it takes about a third of the time compared to the one measuring 100 mm in height.

Expedite $280.17 Made Locally | Standard $280.17 Made Locally | Economy $127.80 Made internationally

I tested another company’s online CNC machining quotation system using the same files. The price rate was different, but the problems remained the same. Perhaps these companies will try to change the parameters to make it look better whenever they read this article!

The important thing to understand here is that if the AI can’t understand these basic CNC machining principles, it will certainly misinterpret other things as well. Yes, you can get a fast quote from the online system. But you might be contacted by human later on, when the company realizes the quotation isn’t accurate, or there are technical issues need to be discussed. Eventually, you will spend the same amount of time getting your parts done as you would with a traditional manufacturing company like us.

This is why we prefer to make the quotation manually. Once we receive the RFQ, it will be passed on to our production engineers straight away. They will come back to our project managers within 12 hours, sometimes much faster with an accurate price as well as a DFM report if needed.

Don’t get me wrong, we’re as excited about new manufacturing technologies as the next company, but sometimes traditional methods just work better.