As a material widely used in everyday items from clocks to knives to bricks to pottery, machining ceramics can be a great way to expand a company’s materials portfolio. Though they are traditionally made using a kiln, machining them can be a useful endeavor that gives your machine shop a unique selling point.

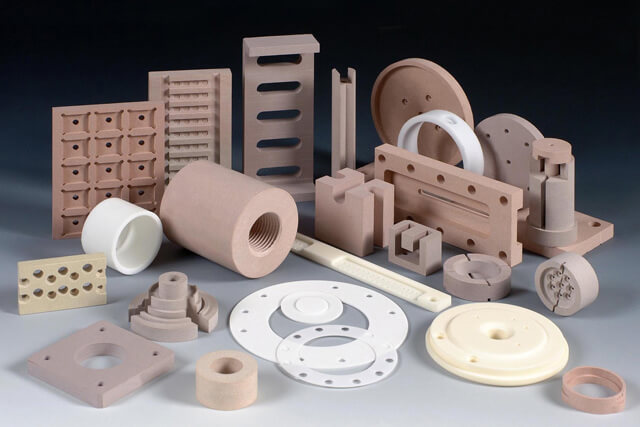

As a CNC machining material class, ceramics come in a variety of forms and machining them can be tricky. However, they are unique in their look and feel, have a great level of compressive endurance (though less in terms of tensile force endurance) and provide a decent basis for a number of different products.

Machining Ceramic Materials

CNC machining ceramics can be a bit of a challenge if they have already been sintered. These processed hardened ceramics can pose quite a bit of a challenge as debris and chunks will fly everywhere. Ceramic parts may be most effectively machined before the final sintering stage either in their “green” (non-sintered powder) compact state or in the presintered “bisque” form.

Generally, machining methods like milling, drilling, turning can be applied to ceramic parts in the presintered state. In terms of tooling, Titanium nitride (TiN) coated high speed steel tools, tungsten carbide tools and polycrystalline diamond (PCD) tools are used in machining of presintered ceramics. In the bisque state, the MRR a machine tool can achieve can match that of tool and die steels.

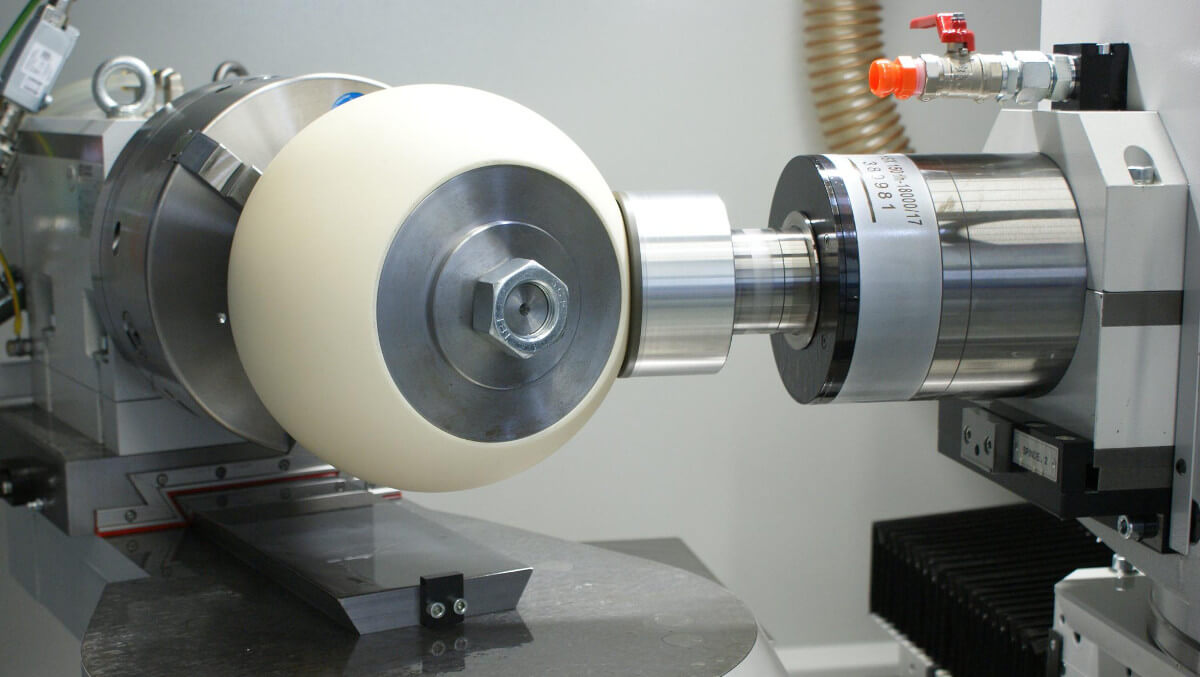

In terms of the sintered state, the most common machining process is that of grinding. With the aid of the abrasive wheel, the machine can achieve a polished surface finish. Grinding ceramics is also best done with fluid coolant that lubricates the region being ground. For sintered ceramics it is best to use resin-bonded wheels with either synthetic or natural diamond of different grit size pressed at different concentrations in polymer resin.

Of course, there are many different types of ceramics and they all have their own characteristics. These are general rules of thumb but these processes can vary.

Types of Ceramics

Macor

Macor is a machinable glass ceramic owned and produced by Corning Inc. It has a bunch of applications in aerospace, medical and semi-conductor production. Using machinable glass ceramics is a cost-efficient way to go when lower-volume quantities need to be produced but high-priced tooling charges are not an option. Macor’s continuous-use temperature is 800°C with a peak temperature of 1,000°C. It’s thermal expansion matches most metals and sealing glasses. Macor is also non-wetting, exhibits zero porosity and, unlike ductile materials, won’t deform. Additionally it is an effective insulator at high voltages, various frequencies and high temperatures. It also won’t “outgas” in vacuum environments.

Alumina

Alumina has good mechanical and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. It can be formed using a wide variety of ceramic processing methods and can be machined or formed to produce a wide variety of sizes and shapes. In addition, it can be readily joined to metals or other ceramics using metalizing and brazing techniques.

Aluminum nitride

Aluminum nitride exhibits lower thermal expansion than alumina that closely matches the expansion of silicon wafers and it can be metalized, making it an ideal material for semi-conductor applications.

Alumina silicate (Lava)

Alumina silicate or Lava is a machinable ceramic material. It has a high use temperature, and excellent thermal / electrical insulating properties.

Boron nitride

Boron nitride can be machined using standard carbide drills. BN exhibits a high electrical resistance, low dielectric constant and loss tangent, low thermal expansion, chemical inertness and good thermal shock resistance. With these properties BN lends itself a useful material for vacuum components, various electrical components and nuclear applications.

Glass (Pyrex, Vycor and similar materials)

Various types of glasse are used in many applications where optical high thermal shock resistance and insulating properties are required.

Graphite

As a carbon based ceramic material, graphite can come in various densities depending on its polymer state. Graphite also has excellent thermal shock and chemical resistance making it an ideal material for molds, furnace boats, plating anodes and brazing fixtures.

Mullite

Mullite is an excellent structural material due to its high temperature stability, strength and creep resistance. It has a low dielectric constant and high electrical insulation capabilities. Typical applications include Kiln Furniture, furnace center tube, heat exchange parts, heat insulation parts and rollers. While mullite is machinable, it is more convenient to laser.

Mycalex

With several grades to choose from, varying in strength and temperature performance, Mycalex is an excellent machinable ceramic insulator material that can be fabricated into complex parts. It is often used for small parts in industrial equipment.

Quartz

With its superior thermal, chemical and optical properties, quartz often is used in the lighting and semi-conductor fields. Best to do these though diamond tools, grinding or water jetting. Abrasive techniques are much more useful than any cutting ones.

Silicon carbide

Silicon carbide is known for its high hardness and abrasion resistance. Common applications include: pump seals, valve components and wear-intensive parts. Despite the high hardness values of this material, it is nevertheless a relatively brittle one and can only be machined using diamond grinding techniques. Typically, it is produced in an Acheson graphite resistance furnace and can be formed as a fine powder or a bonded mass, that must be crushed and milled before it can be used as a powder feedstock.

Steatite

The cost of Steatite is relatively low when compared with other ceramic materials. It’s useful in applications where insulating and temperature resistance are a concern.

Zirconia

Stabilized zirconia offers chemical and corrosion resistance to temperatures well above the melting point of alumina. These characters make it a pretty good material for dental applications and prostheses. It’s high hardness can make it difficult to machine but it helps to process it at high cutting speeds (above 670m/minute). Zirconia ceramics have the ability to absorb great amounts of stress relative to other ceramic materials. It exhibits the highest mechanical strength and toughness at room temperature.

To build a ceramics prototype or product, get in touch with 3ERP for a free quote. or check our service pages for CNC machining and CNC milling services. We’ll gladly offer advice about your best options.